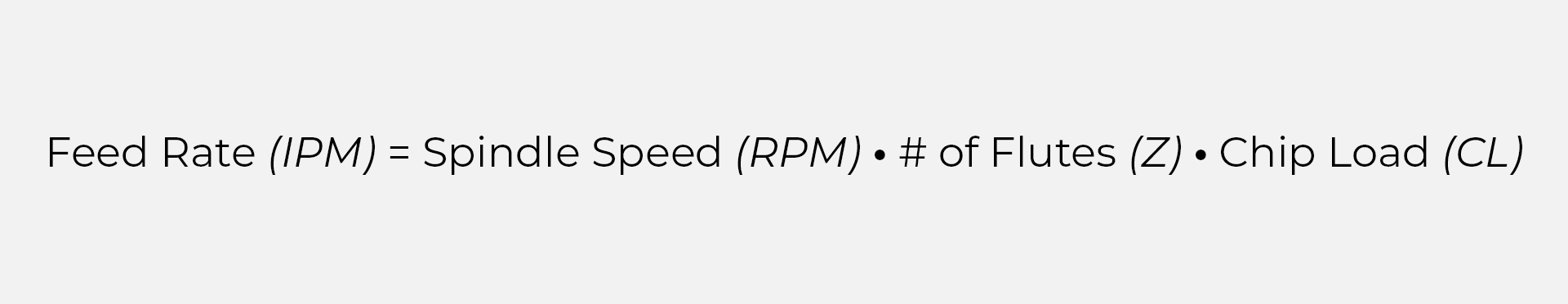

Feed Rate is the linear distance the cutting tool or workpiece travels per unit of time, usually measured in inches per minute (IPM) or millimeters per minute (mm/min).

The linear distance the cutting tool or workpiece travels per unit of time, usually measured in inches per minute (IPM) or millimeters per minute (mm/min).

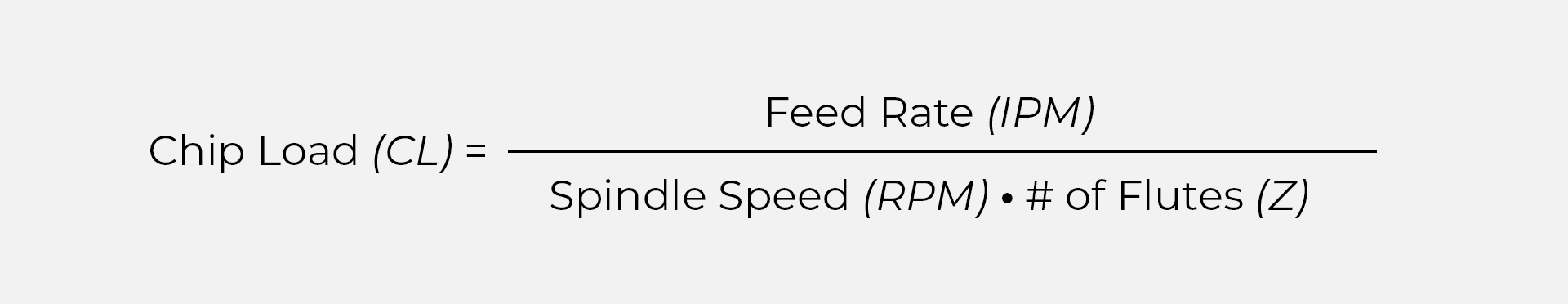

Chip Load is the amount of material removed by each cutting edge of the tool during one revolution of the spindle, typically measured in inches per tooth (IPT) or millimeters per tooth.

Chip load affects tool life, surface finish, and cutting efficiency. Setting the right chip load ensures that the cutting tool is neither underloaded nor overloaded.

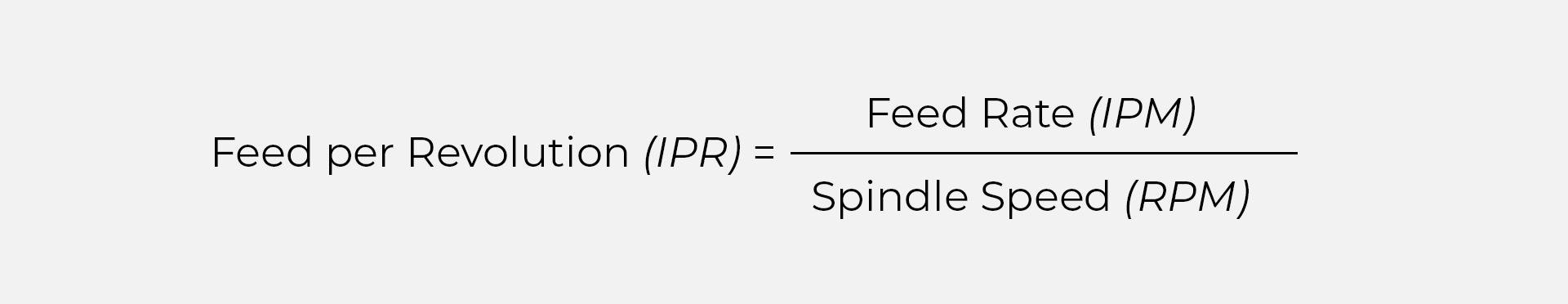

Feed per Revolution is the distance the cutting tool or workpiece advances for each revolution of the spindle, measured in inches per revolution (IPR) or millimeters per revolution.

Feed per revolution is crucial for operations like drilling, where the tool cuts material in a circular motion with each revolution.